DEREK LAMBERT POLYTHENE LIMITED is a private company, is still owned by Mr Lambert. It was formed in the early 1980’s when commercial polymer and film manufacturing began it’s fast ascent to where we are now.

Our business continues to thrive and grow, but we also retain close relationships with many customers that we have worked with since the early days.

We are a friendly, open company with much experience/expertise with a co-operative, helpful spirit when dealing with all others, helping our customers grow their businesses as we grow ours.

We have good working relationships with our suppliers, many over similarly long periods, and enjoy good access to the best and most secure supply lines, materials, information and innovation which we use to produce better products and help our customers achieve long-lasting, consistent success.

History

- 1981- Mr. Derek Lambert founded the company at the present site in Bingley, West Yorkshire.

- 2012- BRC Accreditation achieved for food industry use.

- 1985-2016- Polymer and additive ranges and global supply developed.

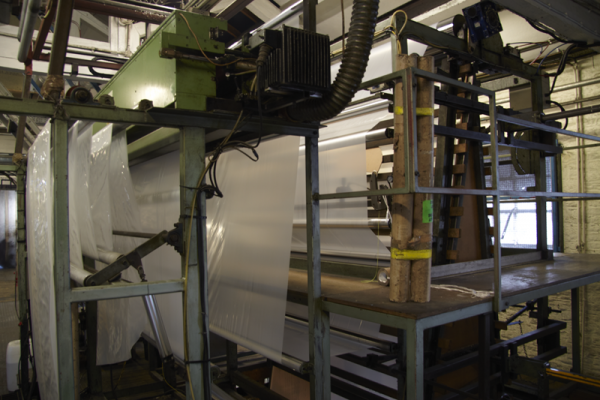

- 1985-2016- In-house manufacturing grew as did the range of machinery.

- 1985-2016- Methods, processes, material combinations and polythene use/applications widen.

Why Choose Us

Flexibility and capacity

Our comprehensive machinery range, production structure, experience and innovative manufacturing methods mean that we are able to respond quickly as market and customer demands fluctuate whilst manufacturing efficiently to keep costs for consistently high-quality products to a minimum. We are one of the best quality manufacturers around in it’s much in our interest to you provide you, our customers, with the product confidence necessary for your customers.

Who are our customers?

The markets we supply to are broad and the countries our products travel to as packaging, protection or otherwise are wide. We produce products for customers at many levels including end users, merchants, retailers/stockists and converters with a vast array of requirements and expectations.

Quality & Consistency – “BRC Certified” means you should know exactly what to expect.

Our long experience means that we are consistently able to match the raw materials and characteristics for the job given the application required, whether that’s technical, economic, environmental or innovation led.

Certified up to BRC food packaging standard and producing all our products using the same processes, means that you can rely on receiving top quality, consistent products, irrespective of which market or application they are destined to fulfil.

Our Manufacturing Site

Compliance

Our raw materials, products and manufacturing site conforms to various quality, operating and trade standards, rules and directives including (but not limited to):

- BRC Global Standards (Packaging and Packaging Materials) Issue 5:2015

- HSE – Operating Safley – Protecting our workforce and visitors to our site

- Certified Prime Raw Materials

- Trade Compliance Rules

- Prime product standards

Recycling

Polythene is a great material, flexible, adaptable, cheap, re-usable, reformable and reclaimable many times over with a little effort. Most of our products are for larger, more industrial applications where collection can be easy and we already use a lot of recycled material in the products we make where the application allows. There is certainly ian increasing demand, so we could use much more and will do so as separation improves and it becomes more abundantly available, protecting more of the resources we have all previously taken for granted.

As innovation improves we will undoubtably be able to utilise those new materials, processes and techniques.

Sustainability

We recycle over 90% of our waste polythene materials internally, the rest externally, re-use wooden pallets and other materials where ever possible.

But sustainability is more than just the environmental impact of our activities. Continuity of our business by manufacturing and dealing with all matters responsibly and reasonably is of great importance to us and our customers to ensure a reliable, mutually beneficent service.

Presence

Most of our products sales and direct deliveries are made to the UK with some to Scandinavia. Our Polythene is mostly used for packaging and protecting goods that are often supplied around the globe, but also in many other applications such as in construction and agriculture.