Extruding film with the right application properties, as cheaply and consistently as possible, is a surprisingly technical process, one that we have developed and fine-tuned over many years.

At Derek Lambert Polythene Ltd. we have always extruded and converted our film in house for flexibility and speed. This does provide significant reaction time advantages over non-extruders to overcome application or short notice delivery changes. Equally, raw material availability, costs and advances do mean that new or equivalent types need rapid testing which we are also able to do.

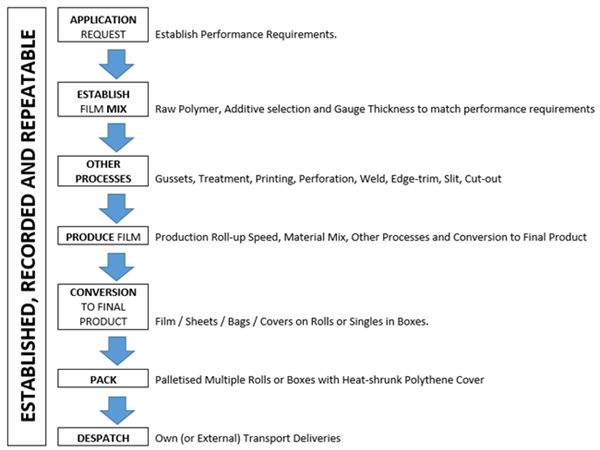

Long-term product quality and application consistency is essential. Our raw materials are electronically weighed and mixed and manufacturing details, material mixes and even the speed and machine used are retained under each customer ‘product’ number and job card.

We work closely with all our customers, initially from the application to match the film performance and then the individual product requirements. In most cases the application has been seen many times before and so the film type is already well established, but samples of material are also supplied when required.